Add to Cart

Water supply pipe 75-160mm high strength PPR extrusion line with mark line

Specification:

The production process of the PP-R pipe is an extrusion molding process. First, the PP-R raw material in the hopper enters the extruder by its own weight, and is heated and extruded in the extruder barrel, and fully plasticized from the extruder port. The die is extruded and enters the setting table. After the shaping, the pipe is passed through the tractor and cut by the cutting machine. The pipe is cut by the cutting machine and the pipe is inspected and put into storage. The corresponding fittings are produced by injection molding.

Pipe production process: PP-R raw material → vacuum suction feeding → hopper storage → feeding → extrusion molding → cooling setting → traction → cutting → inspection → storage

Pipe production process: PP-R raw material → conveying and feeding → hopper storage → feeding → heating and melting → extrusion molding → cooling and setting → mold opening → inspection → storage.

Pipe extrusion parameters: (1) screw speed 5 ~ 38r / min (2) barrel temperature distribution 1 ~ 2 area 180 ~ 190 ° C 3 ~ 4 area 200 ~ 210 ° C mold temperature 200 ° C traction speed 2 ~ 20m / min pipe fittings Injection parameters: (1) barrel temperature distribution barrel rear 160 ~ 170 ° C barrel middle 200 ~ 230 ° C barrel front 180 ~ 200 ° C (2) nozzle 170 ~ 190 ° C (3) mold 40 ~ 80 ° CPP The defective products produced in the -R pipe production process can be reused after being crushed, which improves the utilization rate of raw materials, reduces production costs, and improves economic benefits.

Layout:

Raw material+additive→Mixer→Auto Feeder→Hopper dryer→Single screw Extruder→-Moulds→Vacuum calibration tank→Spray Cooling Tank→Haul-off Unit→Cutting Unit→Stacker

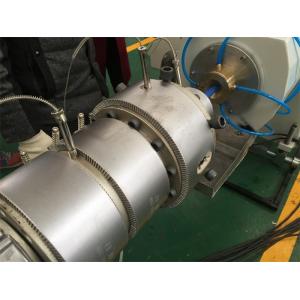

Details specification pictures of PPR pipe production line by BEISU Machinery:

Main technical parameter:

| Model | Pipe Diameter | Output | Haul-off Speed | Total Power | Line Length |

| PPR-63 | 16-63mm | 100-120kg/h | 10m/min | 75kw | 35m |

| PPR-110 | 40-110mm | 180-220kg/h | 6m/min | 145kw | 38m |

| PPR-160 | 50-160mm | 200-250kg/h | 6m/min | 150kw | 38m |

Zhangjiagang Beisu Machinery has a professional and dedicated after-sales service team to provide customers with a full range of responsible and reliable service. Our customer service work is divided into three phases: pre-sales program discussion and design, production tracking and installation and commissioning, and after-sales service and maintenance.

Pre-sales program discussion and design:

According to the customer's actual crushing or processing line requirements, provide customers with the corresponding professional knowledge explanation; at the same time, our engineering team selects the equipment model for you, customizes the most reasonable and effective crushing scheme, and ensures the perfect combination of our equipment and site layout. Create the greatest value and leave you carefree.

We provide customers with the design of the production line process, and truly design a satisfactory and reasonable production line for customers. Often, in order to meet the special needs of our customers and achieve the best results, we will make non-standard design changes to our products and treat every customer with care.